Capabilities

Investment Casting

Maximum Casting Envelope - 36 x 36 X 36

*These are approximations, exact dimensions are contingent on part complexity and requirements.

Maximum Weight - 45 lbs.

Materials Poured:

A356

A357

F357

A355

17-4

15-5

300 Series

400 Series

Low Carbon Alloys

* If your material is not listed here or you need help deciding what alloy is best for your application, please contact us.

Download our casting design guide here.

Machining

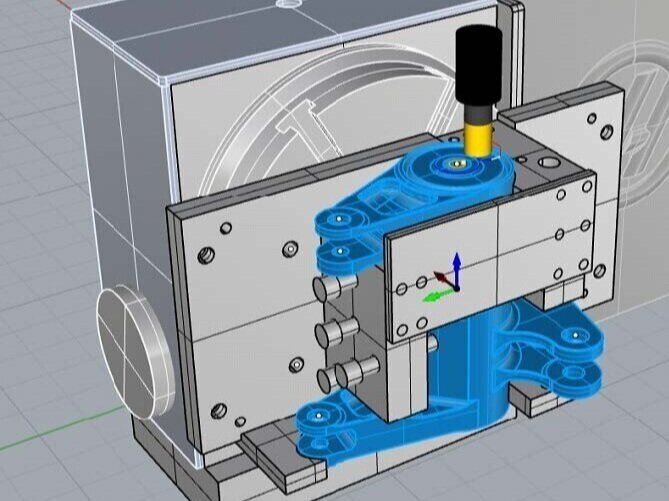

Quality starts from the outset. All of our castings are designed with full 3D solid models consisting of the complete part with 3D simulation in our CAD/CAM systems, ensuring that all our cuts and tool paths are true. Our 4 axis machining capabilities and 30 years of experience allow us to provide fast delivery at competitive prices on all machined casting.

Solidification Modeling

Solidification modeling offers foundry engineers away to simulate the thermal conditions that occur during the investment casting process and develop a gating and assembly technique that produces a compliant part in the most economical manner. Modeling reduces development cost and time for new programs by experimenting with different assemblies and gating prior to actually running the parts, which eliminates the need for expensive and time consuming trial and error. Using the customer supplied CAD model of the casting and our own CAD models of the assemblies. The software is able to simulate the shell building and casting processes.

3D Printing/SLA Prototyping

Complex designs can be uploaded from a CAD model and printed in a few hours. The advantage of this is the rapid verification and development of design ideas. We can turn these ideas into production castings with out the costs of traditional wax molds. Visit the gallery.

Heat Treating

Aurora maintains extensive knowledge and experience in the heat treating. If you have precise needs and mechanical requirements, we have the equipment and expertise to get the job done effectively. NADCAP Heat Treat Certification

Supply Chain Management

Over the course of 40 years Aurora has developed a strong network of approved supplier partners in Southern California. Whether the products are processed in house or processed with one of our capable suppliers, you can count on Aurora to manage the entire process. Visit the gallery.

We offer turn key solutions for:

Chemical & Metallurgical Testing

Non-Destructive Testing

Etch, Passivate, Plating, Prime, Paint

Assembly